Ceramic Coating

Ceramic Coating for Peak Exhaust Performance

Looking to optimize your ride's performance and protect its vital components? Look no further than ceramic coating for your exhaust system. This innovative technology offers a superior alternative to traditional heat management solutions like exhaust wraps and tapes.

The Science Behind the Shield

Ceramic coating is a high-temperature resistant paint applied to exhaust parts. Our coatings range from 1200F to 2200F, ensuring a perfect match for your specific application. The coating acts as a thermal barrier, reflecting heat back into the exhaust stream. This translates to several key benefits:

Enhanced Performance: By reflecting heat away from the engine bay, ceramic coating allows your engine to operate at cooler temperatures. This translates to improved horsepower, torque, and overall efficiency.

Reduced Underhood Temperatures: Cooler exhaust components mean cooler engine bays. This protects surrounding components from heat damage and extends their lifespan.

Improved Efficiency: Hotter exhaust gases exiting the system faster lead to better scavenging, allowing for a more efficient intake cycle.

Ceramic Coating vs. The Competition

While exhaust wraps and heat tapes have been used for heat management, ceramic coating offers several advantages:

-Durability: Ceramic coating is a permanent solution that bonds to the metal, unlike wraps that can degrade over time.

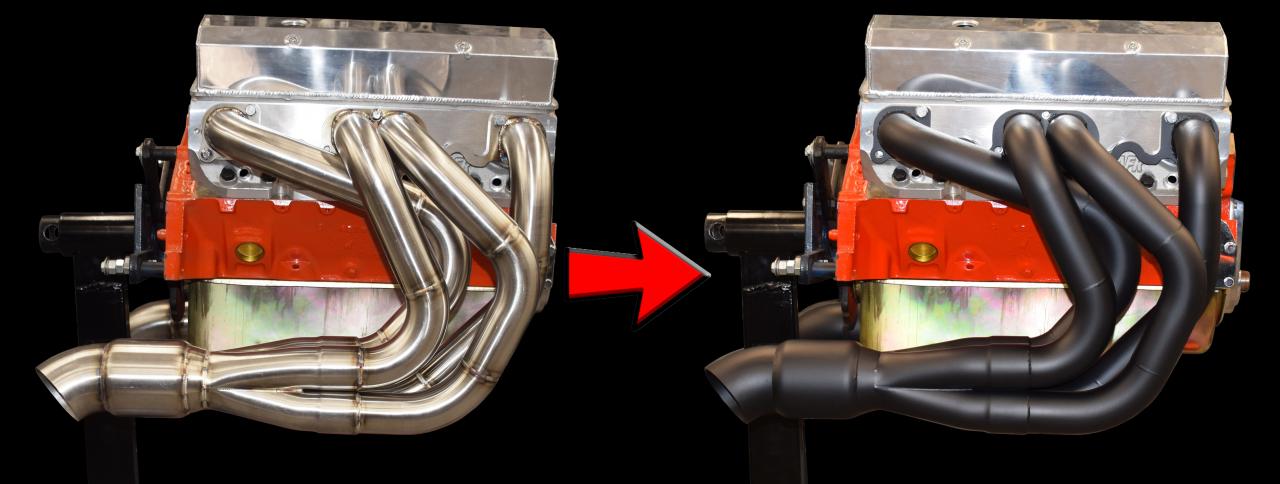

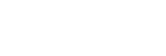

-Performance: Ceramic coating reflects heat, while wraps and tapes insulate it. This allows for more consistent heat management and potentially higher performance gains.

-Ease of Maintenance: Coated parts are easier to clean and inspect compared to wrapped components.

-Aesthetics: Ceramic coating comes in a variety of colors, adding a sleek and custom look to your exhaust system.

Corrosion Resistance: A Shield Against the Elements

In addition to thermal benefits, ceramic coating offers superior corrosion resistance. This is especially crucial for exhaust components made from mild steel, which are susceptible to rust. The coating acts as a barrier, protecting the metal from moisture, road salt, and other corrosive elements. Stainless steel offers better corrosion resistance, but ceramic coating can further enhance its durability, especially in harsh environments.

The Ceramic Coating Process: A Closer Look

Our ceramic coating process is meticulous, ensuring optimal adhesion and performance:

1. Color Choice and Temperature Rating: We work with you to determine the ideal color and temperature rating for your application.

2. Surface Preparation: Sand or media blasting removes paint, rust, and contaminants for proper coating adhesion.

3. Baking and Cleaning: Parts are baked to remove residual gases and oils, then blasted with air and degreased with acetone for a spotless surface.

4. Ceramic Coating Application: The chosen ceramic coating is applied to the prepared components.

5. Curing: Parts are baked in a specialized oven at the manufacturer's recommended temperature to cure the coating.

6. Cool Down and Inspection: The parts are slowly cooled and meticulously inspected before being returned to you.

Invest in Performance and Protection

By choosing ceramic coating for your exhaust system, you're investing in both performance and protection. With its superior thermal barrier properties, corrosion resistance, and durability, ceramic coating is the ultimate solution for any performance enthusiast or driver looking to extend the life of their vehicle. Contact us today to discuss your ceramic coating options and unleash the full potential of your exhaust system!

Color Options Listed Below

Additional Ceramic Coating Galleries Here:

BMW S54 Grey Ice Ceramic Coating